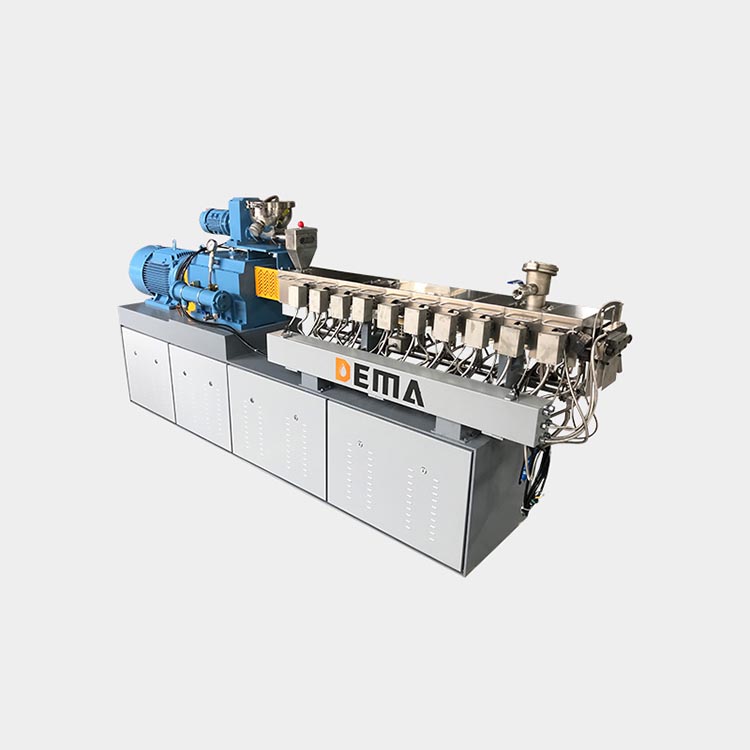

“一” type three-screw extruder

The three-screw extruder plasticizes faster than the twin-screw extruder, has a good mixing effect, has a short residence time of the material at high temperature, and saves energy and electricity.

The three screws of TRI series co-directional parallel three-screw extruder are arranged in a “一” shape and rotate in the same direction at high speed, so that the material is subjected to strong shearing and extrusion, manipulation and grinding, and better homogenization and dispersion. The three-screw extruder has one more high-shear zone than the traditional twin-screw extruder, which doubles the plasticizing and mixing performance of the twin-screw extruder of the same specification, so that high-output extrusion can be achieved. Due to the increase of specific surface area and the increase of surface renewal rate, the devolatilization efficiency is also greatly improved.

Technical Parameters

| Model | Screw Dia. (mm) | L/D | Screw Speed (rpm) | Main Power (KW) | Capacity (kg/h) |

| DMTR 52 | 52.0 | 28-64 | 400-800 | 75-132 | 250-600 |

| DMTR 65 | 62.5 | 28-64 | 400-800 | 90-220 | 500-1200 |

| DMTR 75 | 71.0 | 28-64 | 400-600 | 132-280 | 1500-2500 |

Features:

- It adopts a three-screw structure with the same diameter in parallel to the same direction

- To achieve the purpose of mixing and mixing twin screws under the condition of a small aspect ratio

Applications:

- Blending modification or filling enhancement with high dispersion requirements and large filling amount, such as the preparation of polyolefin high filler, engineering plastic modified material, and high concentration black and white masterbatch.

- Reaction extrusion with high requirements for mixing and mixing, exhaust devolatilization and residence time uniformity, such as XLPE cable material and silane cross-linked cable material