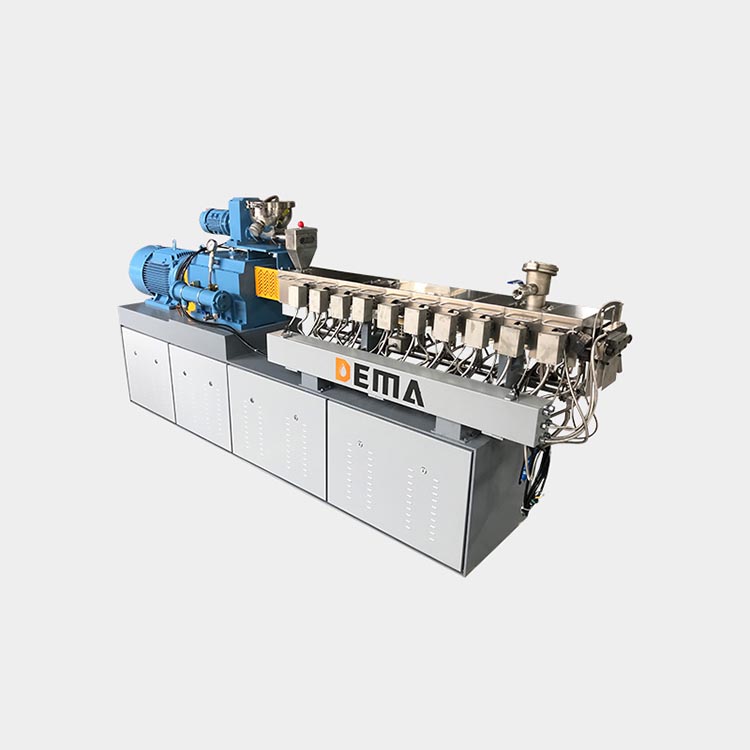

Features of DEMA centrifugal dewatering machine:

- The DEMA dehydrator separates plastic pellet products from water during continuous operation, discharging sufficiently dry products that can be directly packaged or stored, with surface moisture as low as 0.3%.

- The dehydrator does not hide materials, making cleaning convenient and simple. It includes a specially designed dehydration device, which has good dehydration effect, reduces customer drying time, and saves energy

- The body is made of high-quality stainless steel material 304, and the dehydrator is acid resistant, alkali resistant, and corrosion-resistant. It has a beautiful and elegant appearance and a long service life.

- The thickness of the stainless steel material in the body is 5mm, the thickness of the feeding blade is 4mm, and the thickness of the screen mesh is 1.5mm. The locking structure of the dewatering machine screen mesh is specially designed for easy cleaning and screen replacement.

- Advanced and reasonable design, segmented combination, plug-in rotor, high rotation accuracy, main shaft and blades are finely polished and polished, with beautiful particle shape and less powder.

- Each dehydrator must undergo strict dynamic balancing debugging to ensure that the rotor can operate smoothly at high speeds.

- Modular dryer design, replaceable wear-resistant or non stick coating

- Circulating water device, equipped with water tank, water heating, water cooling, and water temperature control module

Basic steps of particle drying in DEMA dehydrator:

The drying operation through the dehydrator during the granulation process includes three separate steps:

- Pre dehydration: up to 95% of the process water is removed by gravity.

- Preliminary drying: A large amount of larger water droplets attached to particles are removed through airflow or mechanical motion.

- Final drying: The dry reverse airflow of the dehumidification fan and the residual heat of the pellets are used to evaporate the remaining surface moisture.

Working principle of DEMA centrifugal dehydrator:

The product and residual water flow into the rotor part of the dehydrator, the rotation speed, and the design of the blades installed on the rotor will cause the product to bounce between the blades and the screen, while being transported upward in a spiral path through centrifugal action. Water is continuously separated through a sieve, and the product is continuously transported to the upper part of the rotor before being discharged from the product outlet. The drying process reduces residual moisture, and the final moisture level depends on the product. The final drying is achieved in the upper third of the screen surface and the product outlet chute of the dewatering machine. The dry countercurrent airflow generated by the dehumidification fan can remove most of the residual moisture on the product surface. In some cases, it is also possible to choose whether to use additional final drying based on the required surface moisture.

Details description of dehydrator:

Body

- The bodyis made of high-quality stainless steel with 5mm thickness

- The sound insulation effect of the bodyis good, the sound pressure level is less than 80 decibels (A)

- The distance between the screen and the bodyis large, making it easy to clean

Screening

- The screen adopts a quick-open structure to achieve rapid disassembly and facilitate cleaning

- For 2mm mesh holes, a plate thickness of 1.4mm mesh is made

- Special design of screen mesh, high strength, no leakage of materials, improve product humidity

- The screen can be customized with different sizes and sizes and mesh shapes according to different materials.

Cooling fan

- The exhaust fan creates a slight vacuum to prevent humid air from entering the box or condensing in downstream equipment components

- Pump away the water mist generated during high-speed dehydration

- Integrated dehumidifier fan is a standard configuration for improving drying efficiency

- Customized fan with all stainless steel

Rotor

- Advanced and reasonable design, segmented combination, insert-type rotor, high rotation accuracy

- The spindle and blades have been polished and polished, with beautiful particles and few powders

- Special design to increase equipment stability

- Thickened blades with all stainless steel can effectively extend service life, and the blades can increase wear-resistant or non-stick coating

Water circulation system

- It can be equipped with heater, cooler, liquid level control automatic water replenishment and water temperature control system

- Double-layer filter for easy cleaning (filter box drawer)

- All boxes are made of stainless steel wire drawing board

- Minimize the amount of water replenishment or avoid higher water losses