Twin screw extruder is outstanding due to high efficiency and versatility in industrial manufacturing and material processing. From plastics and food to medical and chemicals industry, this advanced machine is important for making products by compounding, reactive extrusion, and product formation. How does a twin screw extruder work? This article explores twin screw extruder working principle in polymer compounding, explaining its components and mechanisms to help you better understand and have more perspectives of solving its common problems.

What is Twin Screw Extruder?

Twin screw extruder is a machine that equipped with two intermeshing screws inside a barrel to process raw materials. These two screws can rotate in the same direction (co-rotating) or opposite directions (counter-rotating). Compared to a single screw extruder, the twin screw design offers superior mixing, conveying, and shearing capabilities. It makes twin screw extruder ideal for complex tasks such as blending polymers, devolatilizing, and carrying out chemical reactions.

Key Components of Twin Screw Extruder

1. Feed Hopper: The entry point for raw materials (pellets, powders, or liquids).

2. Barrel: A heated housing that contains the screws and facilitates temperature control.

3. Twin Screw Elements: The key components of the machine. These screws are modular, allowing customization of screw shape for specific functions.

4. Drive System: Provides the torque and speed to rotate the screws.

5. Die: Shapes the final extruded product into strands, sheets, or profiles.

6. Control System: Monitors and regulates parameters like temperature, screw speed, and pressure.

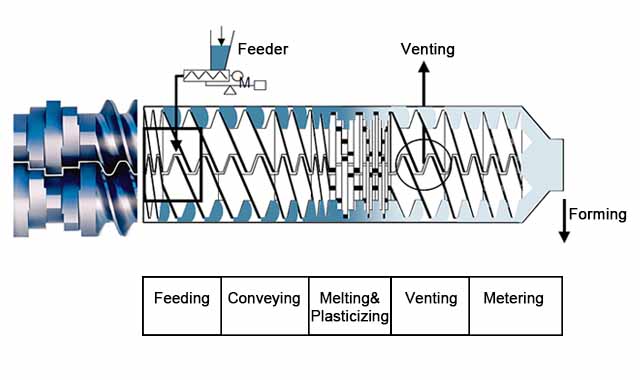

Twin Screw Extruder Working Principle: Step-by-Step Process

The operation of a twin screw extruder follows a continuous, multi-stage process within a single machine. Here’s a breakdown:

1. Feeding

The process begins at the feed hopper, where raw materials are introduced. A consistent feed rate is crucial for stable twin screw extruder operation. Specialized feeders ensure precise delivery of various components in a formulation.

2. Conveying and Solids Conveying Zone

The intermeshing screws grab the material and convey it forward through the barrel. This initial section, often unheated, primarily transports the solid feedstock.

3. Melting and Plasticating

As the material moves into heated barrel zones, it begins to melt. The twin screw extruder principle of intermeshing creates intense shear and compressive forces between the screws and the barrel wall. This friction, combined with external heating, rapidly plasticizes the material. The superior mixing action here is a key advantage over single-screw machines.

4. Mixing and Venting

This is the core of the twin screw extruder’s functionality. The modular screw design allows for the combination of specialized mixing elements (kneading blocks, toothed gears) that create dispersive and distributive mixing. This ensures uniformly blending of additives, fillers, or multiple polymers. Venting ports can be opened along the barrel to remove moisture, air, or volatile by-products—a process known as devolatilization.

5. Pumping and Establishing Pressure

After mixing, the fully molten and homogenized material is conveyed to the metering section. The screw geometry here builds the necessary pressure to force the material uniformly through the die.

6. Die Forming and Cooling

The material exits through a die, which gives it its final shape (e.g., strands for pelletizing, sheets, or profiles). The extrudate is then cooled, typically using a water bath or air, to solidify its form.

Troubleshooting Twin Screw Extruder Problems

Based on the working principles of twin screw extruder and our years of experience, there are common problems can be solved as following:

1. Unstable Main Motor Current

1) Irregular Feeding: Check for material buildup on the feeder screw. Clean it thoroughly. Ensure premixed material is uniform.

2) Mechanical Wear: Inspect feeder motor bearings for damage or poor lubrication. Repair or replace as needed.

3) Insufficient Heating: If barrel zones fail to reach set temperatures, material may not plasticize properly, causing torque spikes. Check and repair faulty heaters or bands.

2. Machine Fails to Start

1) Lubrication: Confirm the oil pump is running and system pressure is adequate.

2) Temperature: Ensure barrel and die head zones have reached their minimum startup temperatures.

3) Screw Phase Error: Improperly timed screws drastically increase torque. Solution: Retract screws, realign timing marks, and reinsert. Always hand-rotate (barrel clean!) before power-up to verify free movement.

4) Electrical Faults: Reset tripped circuit breakers, contactors, or motor starters. For persistent controller issues, consult a qualified electrician.

3. Inaccurate Temperature Control

1) Sensors: Verify controller and thermocouple readings. Ensure thermocouples are fully seated and undamaged.

2) Heaters: Check heater band connections and resistance for burnouts.

3) Cooling: Confirm cooling water valves (manual or solenoid) open properly. Check for clogged barrel channels preventing adequate heat removal.

4. Poor or No Vacuum Effect

1) Leaks: Inspect seals on vacuum hoppers, barrel vent ports, and pipe connections. Ensure the vent stack chamber is clean and sealed.

2) Blockages: Clear any material clogging vent ports or pipes. Verify all valves in the vacuum line are open.

3) Pump Issues: Check vacuum pump operation. Prevent water backflow to the barrel by ensuring the pump isn’t overloaded and that the vacuum tank drain valve is closed during operation.

If you’re facing a specific issue not covered here, describing your material and problems can help us in judging more complex twin screw extruder failures.

Conclusion

The twin screw extruder can transform plastic raw materials into high-value, consistent products through a continuous and controlled process. Its working principle, centered on the cooperation of two intermeshing screws, provides excellent mixing, venting, and conveying performance. Understanding the working principle of twin screw extruder is crucial to optimizing your processes and innovating with new materials.