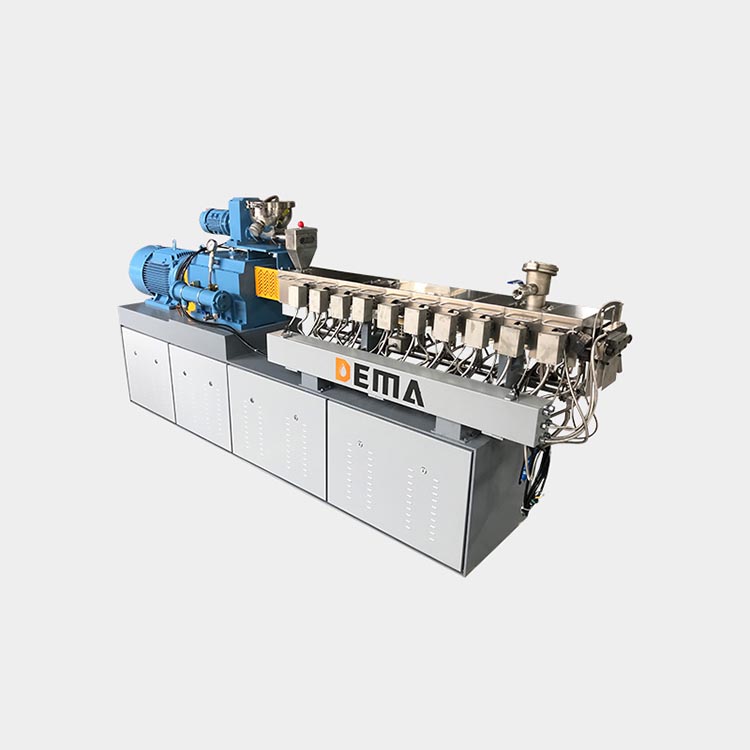

DMTH series twin-screw extruder is defined as high torque type. The processing part is composed of two screw mandrels, screw elements and cylinders that rotate in the same direction.

We make various technological innovations every year according to the needs of customers and the market with strong R&D capabilities. It could meet to some middle and high-end customers with improved requirement for capacity and quality. It is highly practical, stable and received good reputation.

Technical Parameters

| Model | Screw Dia. (mm) | L/D | Screw Speed (rpm) | Main Power (KW) | Torque (T/A3) | Capacity (kg/h) |

| DMTH 35 | 35.6 | 28-68 | 600 1000 | 30 45 | 8.7 | 75-150 100-200 |

| DMTH 40 | 41.1 | 28-68 | 600 1000 | 45 75 | 8.7 | 100-200 150-350 |

| DMTH 52 | 51.4 | 28-68 | 600 900 | 90 132 | 8.7 | 200-400 300-600 |

| DMTH 65 | 62.4 | 28-68 | 600 900 | 160 220 | 8.7 | 400-800 500-1000 |

| DMTH 75 | 71.0 | 28-68 | 600 800 | 250 315 | 8.7 | 600-1500 800-1600 |

| DMTH 85 | 81.0 | 28-68 | 600 800 | 315 450 | 8.7 | 800-1600 1000-2000 |

| DMTH 95 | 93.0 | 28-68 | 600 700 | 500 600 | 8.7 | 1200-2500 1500-3000 |

| DMTH110 | 108 | 28-68 | 500 600 | 630 800 | 8.7 | 1500-3000 2000-4000 |

Features

♦ Screw elements

It includes of various types and materials can meet the requirements of various properties and processing techniques of materials, which can realize the conveying, mixing, mixing, shearing, devolatilization, reaction, compression and other functions of the material with the combination of processing performance. The screw length-diameter ratio can be adjusted according to the processing technology.

♦ Cylinder

with high machining accuracy. It normally has closed cylinder, feeding cylinder, and exhaust cylinder.

♦ Motor

AC motor and DC motor are available according to the characteristics of the model.

♦ Gearbox

It adopts a new type of gearbox system with high torque, high speed and high output developed by our company, which has stable quality and excellent performance since it was put into the market.

♦ Feeding mode

We offer a variety of feeding modes and feeding units which can realize the measurement and quantitative addition of various materials. In addition to the normal main, side or liquid feeding, our feeding units also include vertical forced feeding and conical feeding, as well as loss-in-weight multi-feed metering systems.

♦ Electrical control systems

Equipped with various levels of electrical and automated control systems

应用

According to the customer’s process and requirements, can produce a variety of materials of screw extrusion units. which application to modification, reaction, filler, extrusion molding etc.