Filler masterbatch is normally filled PE / PP carrier with different percentage of calcium carbonate(CaCO3), talc, kaolin or other inorganic powder in order to enhance, increment output, reduce costs, improve heat resistance of plastic raw material and low-carbon environment.

应用

This masterbatch can be widely used in PE, PP, PS, ABS and other plastic products, such as: plastic films, hollow products, pipes, sheets, injection-molded products, and plastic fast food boxes.

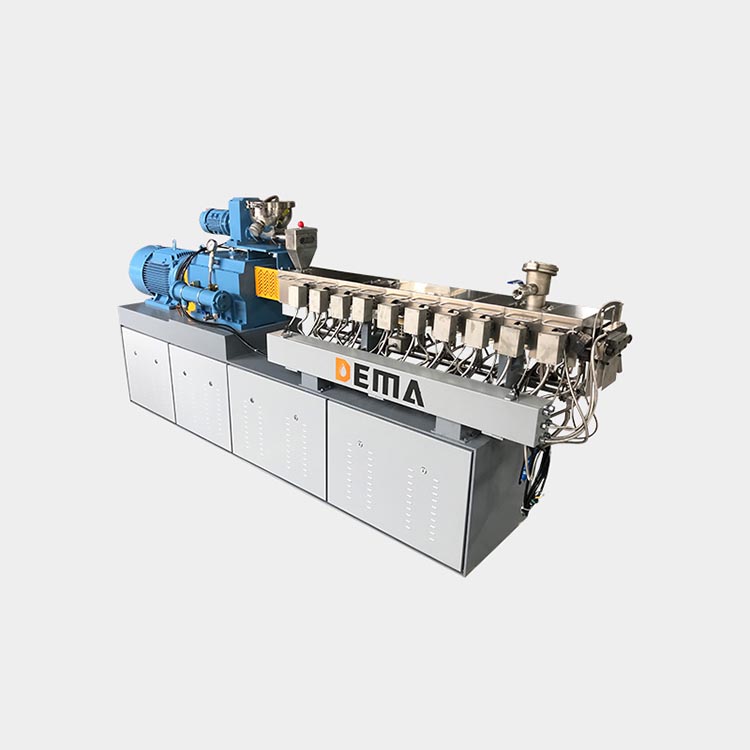

Our twin-screw extruder is suitable for high-fill and high-performance formulations of plastic filler masterbatch. We optimize the screw configuration includes the layout and quantity of kneading blocks and reverse-thread elements to control the shearing precision. It has high efficiency of mixing and dispersion with high uniformity.

Product Parameters

Model | Screw dia. (mm) | L/D | Main power (kw) | Screw speed (rpm) | Capacity (kg/h) |

DMTA 65 | 62.4 | 48-52 | 110 | 600 | 400-600 |

DMTA 75 | 71 | 48-52 | 160 | 600 | 700-1000 |

| DMTH 75 | 71 | 48-52 | 250 | 600-800 | 1000-1600 |

| DMTV 77 | 71 | 48-56 | 315 | 600-900 | 2000-2500 |