Different material needs specific cutting system, DEMA provides all kinds of cutting system, below is the introduction of our main cutting systems.

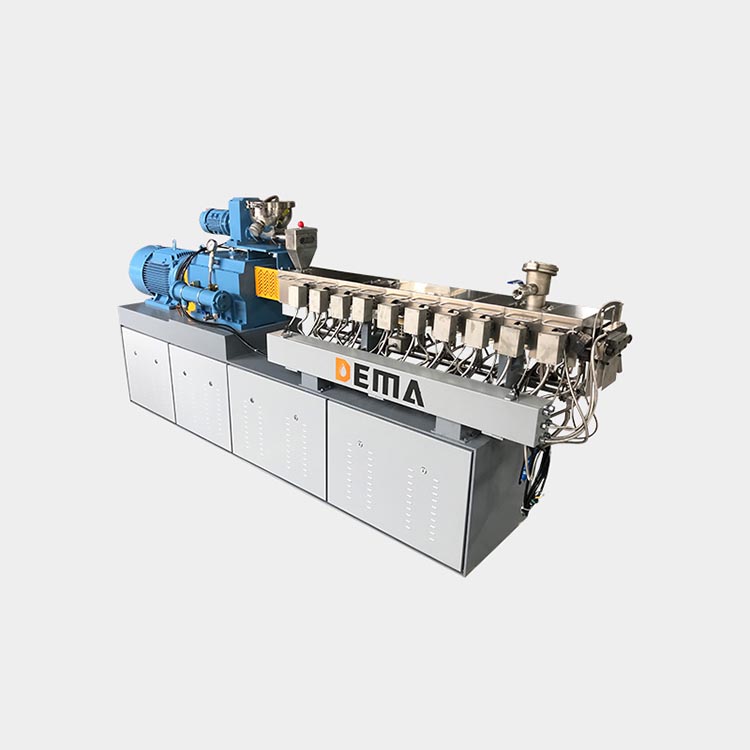

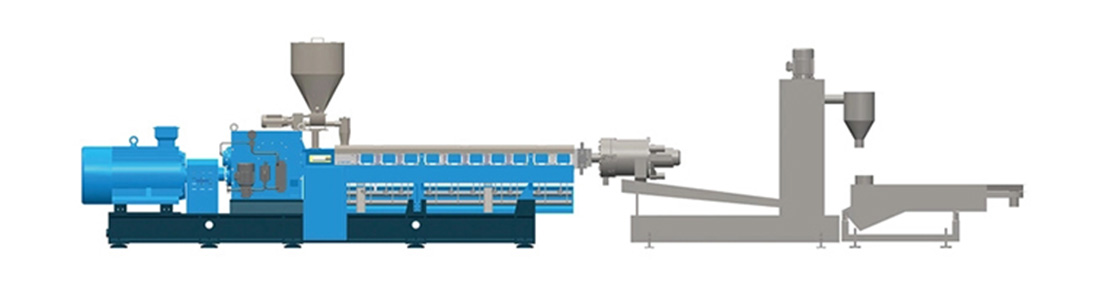

1. Water cooling strand pelletizing line

This cutting type is suitable for the granulation of almost all kinds of common thermoplastic engineering plastics and modification engineering plastics, such as ABS, PA, PC, PE, PET, POM, PP, PPS, PS, etc., including glass fiber reinforced and inorganic filling thermoplastic extrusion.

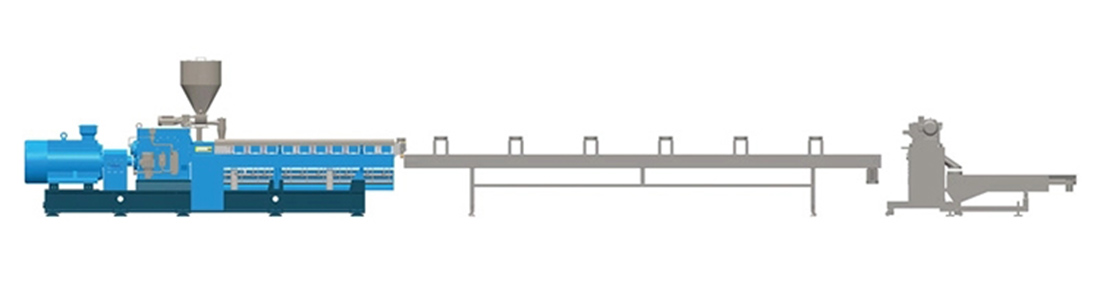

2. Air cooling strand pelletizing line

This cutting type is suitable for the compounding of biodegradable materials such as PLA,PBAT, PBSPPC, PHA and starch/filler.

It is mainly used for materials with high filling capacity, difficult to dry after putting in water, and more sensitive to water to ensure material quality. The process has the characteristics of simple equipment structure, convenient operation and maintenance.

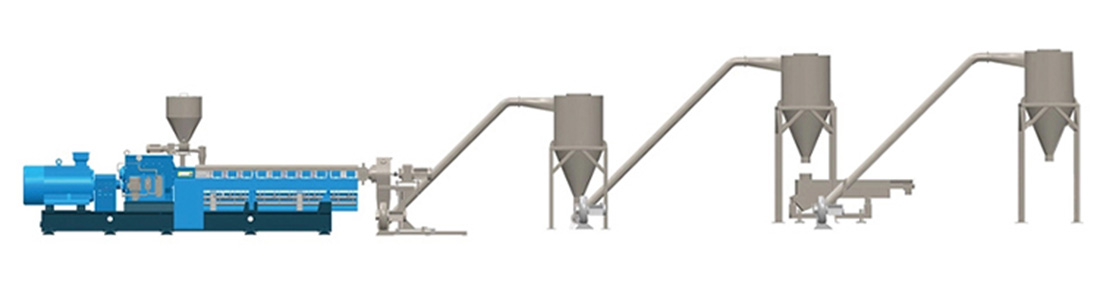

3. Air cooling hot-face pelletizing line

This cutting type is widely used in wood plastic granulation and PVC modification,such as PE/PP+wood powder, PVC+ CaCO3,etc.

It don’t contact with water during the whole pelletizing process, so this pelletizing system is more suitable for the materials which is easy to absorb water,or not easy to be dewatered/dried, or its quality would be damaged by the moisture content.

4. Water-ring hot-face pelletizing line

This cutting type is widely used to produce many thermoplastic material,especailly PP/PE + CaCO3, talc powder, titanium dioxide and other high filling masterbatch.

The water ring mold don’t contact with the cooling water because its flow channel is set on the periphery of the mold. This structure ensure the uniform temperature of the mold, as well as the consistency and uniformity of the particle material with good appearance.

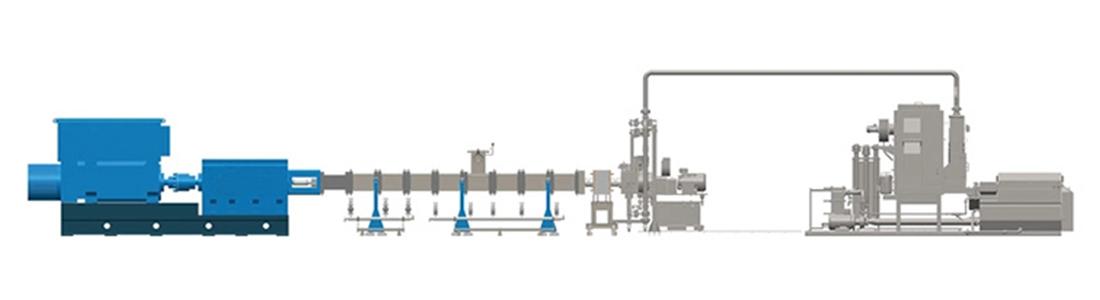

5. Underwater pelletizing line

This cutting type is suitable for most of materials especially leading in high capacity granulation, or producing low-hardness thermoplastic elastomer material includes EVA, TPR, TPE, TPU, SBS, etc which other pelletizing system is not easy to cut off or easy to stick together again.

It cut the material into granules immediately after coming out from die head and flow into water directly, which increases the cooling efficiency as well as makes good surface shape, high density and less oxidation of granules.

If you want more information or not sure of which cutting system is suitable for your application, please send your requirement to discuss with us together.