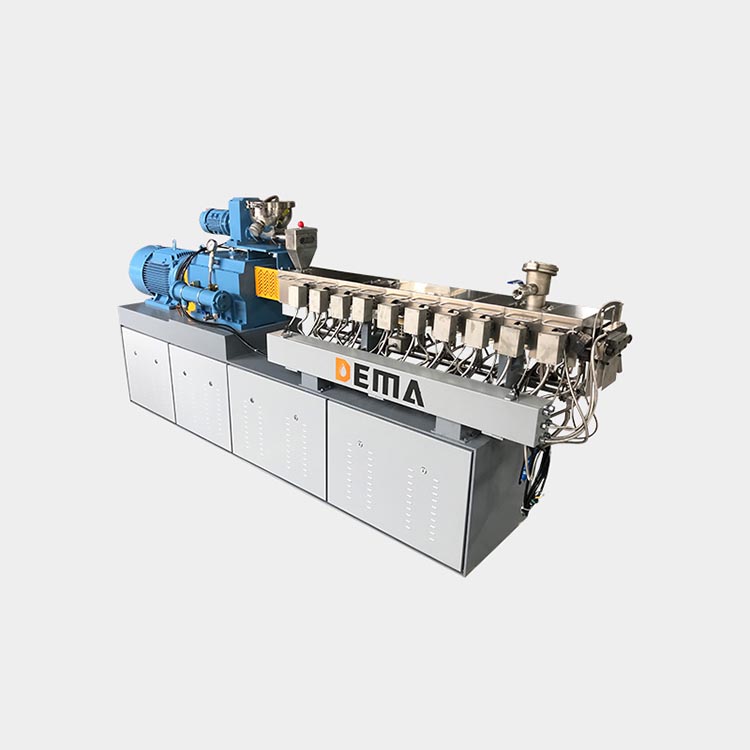

DEMA provides advanced extruder for TPE/SBS/TPU/TPR/EVA compounding.

Thermoplastic Elastomers (TPE) combine the elasticity of rubber with the processing advantages of plastics, with extensive applications across multiple industries.

Applications of main types

1. TPS (SEBS/SEPS-based): Toys, daily products

2. TPO/TPV: Automotive seals

3. TPU: Premium footwear, industrial belts

4. TPEE: Sports equipment, medical devices

Our underwater pelletizing line is suitable for most of materials especially leading in high capacity granulation, or producing low-hardness thermoplastic elastomer material which other pelletizing system is not easy to cut off or easy to stick together again.

1.One-click startup, convenient and fast to operate.

2.Reduce the footprint and curing time, optimize the shape of granules.

3.Energy conservation by lower demand of cooling water.

4.Environmental protection. Fully enclosed production with low noise and dust.

Product Parameters

Model | Screw dia. (mm) | L/D | Main power (kw) | Screw speed (rpm) | Capacity (kg/h) |

DMTA52 | 51.4 | 44-56 | 55 | 300-600 | 150-250 |

| DMTA65 | 62.4 | 44-56 | 90/110 | 300-600 | 200-350 |

DMTA75 | 71 | 44-56 | 132/160 | 300-600 | 350-500 |

| DMTH75 | 71 | 44-56 | 200/250 | 300-600 | 500-750 |